Metal

Silver & Gold

Precious metals like silver and gold are very soft. Silver is a tricky material to mark as it oxidizes and tarnishes easily. Gold can be very easy to mark, requiring little power to get a good, contrasting anneal.

Each and every BEC Laser series is capable of marking on silver and gold and the ideal system for your application depends on your marking requirements. Because of the value of these substrates, engraving and etching are not common. Annealing allows the surface oxidation to create contrast, removing only a negligible amount of material.

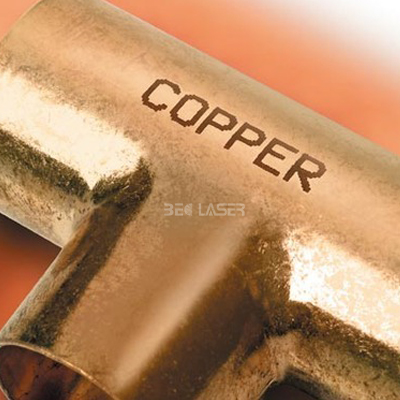

Brass & Copper

Brass and copper have high thermal conductivity and thermal transfer properties and are used commonly for wiring, printed circuit boards and pressurized flow meters. Their thermal properties are ideal for laser marking systems for metal because the heat is quickly dissipated. This reduces the impact the laser can have on the structural integrity of the material.

Each and every BEC Laser series is capable of marking on brass and copper and the ideal system for your application depends on your marking requirements. The best marking technique depends on the finish of the brass or copper. Smooth surfaces can offer a soft polished marking affect, but they can also be annealed, etched, or engraved. Granular surface finishes offer little opportunity for polish. Etching or engraving is best in order to provide readability by humans and machines. In some cases a dark anneal can work, but surface irregularities can cause reduced readability.

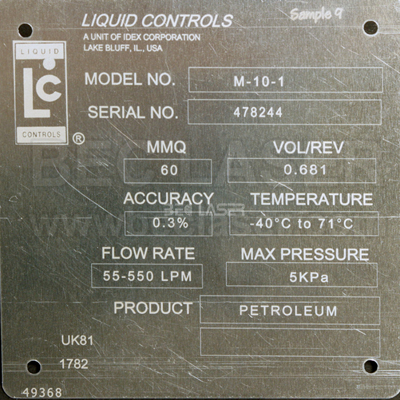

Stainless Steel

Next to aluminum, stainless steel is the most commonly marked substrate we see at BEC Laser. It is used in virtually every industry. There are several types of steels, each with varying carbon content, hardness, and finishes. Part geometry and size also vary greatly, but all allow for a variety of marking techniques.

Each and every BEC Laser series is capable of marking on stainless steel and the ideal system for your application depends on your marking requirements. Stainless steel lends itself to every laser marking technique used today. Carbon migration or annealing is rather simple and black anneals can be achieved with low or high wattage. Etching and engraving are also easy, because the steel is absorbent and is good enough at thermal transfer to help mitigate damage. Polish marking is possible, too, but it’s a rare choice because most applications require contrast.

Aluminum

Aluminum is one of the most commonly marked substrates and is used in many industries. Typically, with lighter marking intensity, aluminum will turn white. It looks good when the aluminum is anodized, but white marking is not ideal for bare and cast aluminum. More intense laser settings provide a dark grey or charcoal color.

Each and every BEC Laser series is capable of marking on aluminum and the ideal system for your application depends on your laser marking requirements. Ablation is the most common marking technique for anodized aluminum, but some cases call for etching or engraving. Bare and Cast aluminum are typically annealed (resulting in a white color) unless a specification calls for greater depth and contrast.

Titanium

This lightweight super alloy is used heavily in medical and aerospace applications because of its strength, durability and limited mass. Industries that utilize this material carry heavy liability and need to ensure that the marking being performed is safe and non-damaging. Aerospace applications require heavy fatigue testing to ensure no structural damage is incurred by the titanium part by way of Heat Affected Zones (HAZ), recasting/remelt layers, or micro-cracking. Not all lasers are capable of performing such markings. For the medical industry, most titanium parts are actually placed inside of the human body permanently, or for surgical tools which will be used inside of the human body. Because of this, markings must be sterile and durable. Also, these marked parts or tools must be approved by the FDA to ensure that they are truly inert and safe for their intended use.

Each and every BEC Laser series is capable of marking on titanium and the ideal system for your application depends on your marking requirements. Titanium lends itself to all marking techniques but the best laser and technique depend on the application. The aerospace industry uses annealing to limit structural damage. Medical instruments are annealed, etched or engraved depending on the intended lifecycle and use of the implement.

Coated & Painted Metal

There are many types of coatings used to harden or protect metals from corrosive elements. Some coatings, such as powder coat, are thicker and require more intense laser settings to completely remove. Other coatings, like black oxide, are thin and meant to protect only the surface. These are much easier to ablate and will provide great contrast marking.

Each and every BEC Laser series is capable of marking on coated and painted metals and the ideal system for your application depends on your marking requirements. The UM-1 provides plenty of power to remove or ablate thinner coatings. It may not be ideal for removing a powder coat but it can easily mark a powder coat. Our more powerful fiber lasers come in 20-50 watts, and can easily remove the powder coat and mark the underlying surface. Our fiber lasers can ablate, etch and engrave coated metals.