Laser Marking & Engraving for Packaging

With the continuous improvement of living standards, while the consumption power continues to grow, people's requirements for packaging are also continuously strengthened. The application of laser marking machine in the food and beverage industry is a new trend. Not only can the food surface or packaging surface be marked with various information such as codes, logos or origin, but also can be marked by laser marking on the outer packaging of canned products. With the shelf life and bar code information, it can be said that the laser marking machine has witnessed the development of the food packaging labeling industry.

The packaging industry has always used inkjet printers. It has to be said that inkjet printers have indeed made indelible contributions to the packaging industry in the past. But the ink jet printer has a very bad point, that is, the marks it prints are not deep, and it is easy to be erased and modified. Because of this defect in the ink jet printer, many illegal businesses erase the production date when the product is about to expire, and then mark the new production date. Therefore, in order to effectively improve the durability of the marking information, the use of laser marking machines for marking is now a more effective measure.

The wavelength of the co2 laser marking machine is very suitable for marking applications on the packaging box printing, because the wavelength of the co2 laser can just bleach the pigments and leave a clear white mark on the packaging box. At the same time, the marking speed of CO2 laser marking machine is very fast, unless the power of the laser is not high, the laser marking of ID information or production date can be completed.

Laser marking is a non-contact processing method that uses laser beams to mark various fine and complex texts, graphics, barcodes, etc. on the surface of packaging materials. Different from inkjet coding and sticking labels, the marks made by laser are permanent, not easy to be erased, waterproof and corrosion-proof, no chemical pollution in the marking process, no consumables such as ink and paper, the equipment is stable and reliable, and almost no maintenance is required. The entire marking process is completed automatically, with fast time and high efficiency.

At the same time, it also has a powerful information traceability function, which greatly improves the efficiency of product packaging and makes quality monitoring and market circulation traceability more convenient and effective.

Advantages of laser marking machine application of packaging:

Reduce production costs, reduce consumables, and increase production efficiency.

Fast speed, high precision, stable performance, fine lines.

The anti-counterfeiting effect is obvious, laser marking technology can effectively inhibit the product logo counterfeiting.

It is beneficial for product tracking and recording. The laser marking machine can produce the batch number production date, shifts, etc. of the product. Can make every product get a good track performance.

Adding additional value. Improve product brand awareness.

Due to reliability of the equipment, a mature industrial design, and stable and trustworthy performance, laser engraving (marking) can work 24 hours a day.

Environmental protection, safety, laser marking machine does not produce any harmful chemicals on the human body and the environment.

Application examples

Plastic bottle marking

Food packaging marking

Tobacco packaging marking

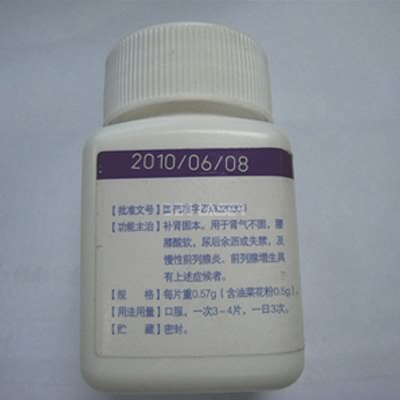

Pill box packaging marking

Marking of wine bottle caps