Non-Metal

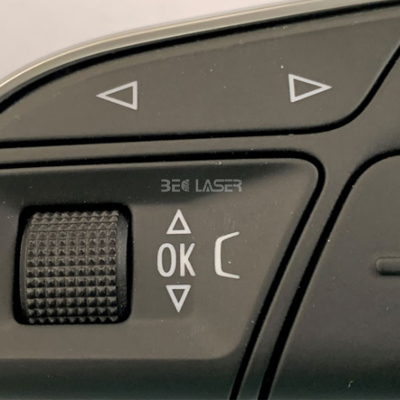

BEC Laser Marking Systems are capable of marking a variety of different materials. The most common materials are metals and plastics but our lasers are also capable of marking on ceramics, composites and semiconductor substrates like silicon.

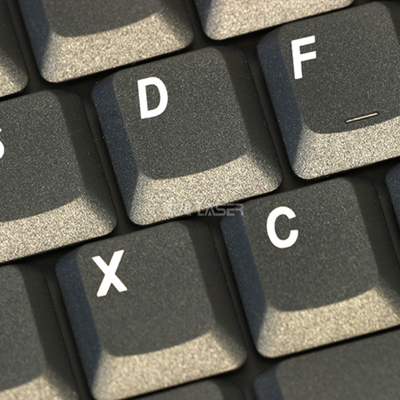

Plastics&Polymers

Plastics and polymers are by far the most expansive and variable materials that are marked with lasers. There are so many different chemical compositions that you cannot categorize them easily. Some generalizations can be made in terms of markings and how they will appear, but there is always an exception. We recommend test marking to ensure the best results. A good example of material variability is delrin (AKA Acetal). Black delrin is easy to mark, providing stark white contrast against the black plastic. Black delrin is truly an ideal plastic for showcasing the capabilities of a laser marking system. However, natual delrin is white and does not mark at all with any laser. Even the most powerful laser marking system will not make a mark on this material.

Each and every BEC Laser series is capable of marking on plastics and polymers, the ideal system for your application depends on your marking requirements. Because plastics and some polymers are soft and can burn while marking, Nd: YVO4 or Nd:YAG may be your best bet. These lasers have lightning fast pulse durations resulting in less heat on the material. 532nm Green lasers can be ideal as they have less thermal energy transfer and also are better absorbed by a wider range of plastics.

The most common technique in plastic and polymer marking is color changing. This type of mark uses the energy of the laser beam to alter the molecular structure of the piece, resulting in a change in the color of the substrate without damaging the surface. Some plastics and polymers can be lightly etched or engraved, but consistency is always a concern.

Glass & Acrylic

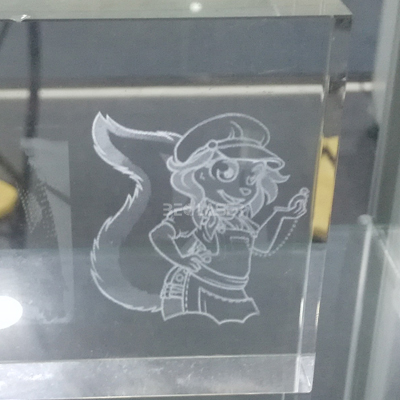

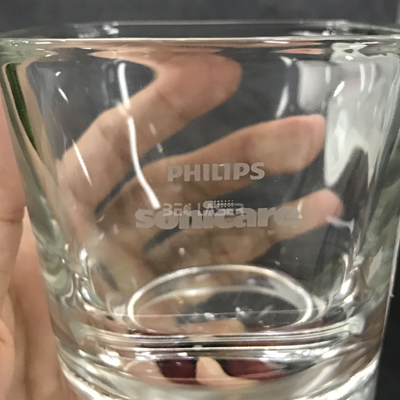

Glass is a synthetic fragile product, transparent material, although it can bring all kinds of convenience to production, but in terms of appearance decoration has always been the most wanted to change, so how to better implant various patterns and text the appearance of glass products has become a goal pursued by consumers. Since glass has a better absorption rate for UV lasers, in order to prevent glass from being damaged by external forces, UV laser marking machines are currently used for engraving.

Engrave glass simply and precisely with a BEC laser engraving machine. Laser etching glass produces a fascinating matte effect. Very fine contours and details can be etched into glass as photos, lettering or logos, e.g. on wine glasses, champagne flutes, beer glasses, bottles. Personalized gifts for parties or corporate events are memorable and make laser-engraved glass unique.

Acrylic, also known as PMMA or Acrylic, is derived from Organic Glass in English. The chemical name is polymethyl methacrylate. It is an important plastic polymer material that has been developed earlier. It has good transparency, chemical stability and weather resistance, easy to dye, easy to process, and beautiful in appearance. It is used in the construction industry. Has a wide range of applications. Plexiglass products can generally be divided into cast plates, extruded plates and molding compounds. Here, BEC Laser recommend using CO2 laser marking machine to mark or engrave Acrylic.

The marking effect of CO2 laser marking machine is colorless. Generally, transparent acrylic materials will be white in color. The plexiglass craft products include: plexiglass panels, acrylic signs, plexiglass nameplates, acrylic carved crafts, acrylic boxes, photo frames, menu plates, photo frames, etc.

Wood

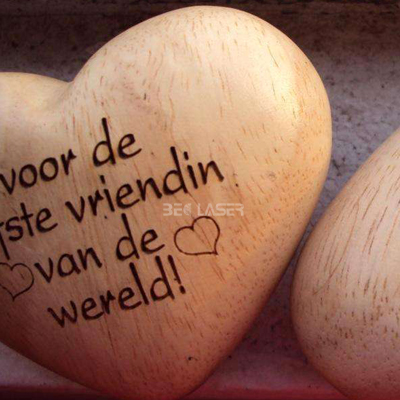

Wood is easy to engrave and cut with a laser marking machine. Light-colored wood like birch, cherry or maple can be gasified by laser well, so it is more suitable for carving. Each kind of wood has its own characteristics, and some are denser, such as hardwood, which requires greater laser power when engraving or cutting.

With BEC laser equipment, you can cut and engrave toys, arts, crafts, souvenirs, Christmas jewelry, gift items, architectural models and inlays. When laser processing wood, the focus is often on personal customization options. BEC lasers can process a variety of wood types to create the look you like.

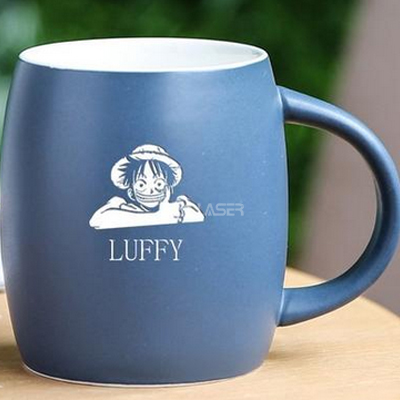

Ceramics

Non-semiconductor ceramics come in a variety of shapes and forms. Some are very soft and others are hardened providing a lot of variety. In general, ceramics are a difficult substrate to laser mark as they do not typically absorb a lot laser light or wavelength.

BEC Laser offers laser marking system that is better absorbed by certain ceramics. We recommend you have test sampling done to determine the best marking technique to apply to your ceramic material. Ceramics that can be marked are often annealed, but etching and engraving are sometimes possible, too.

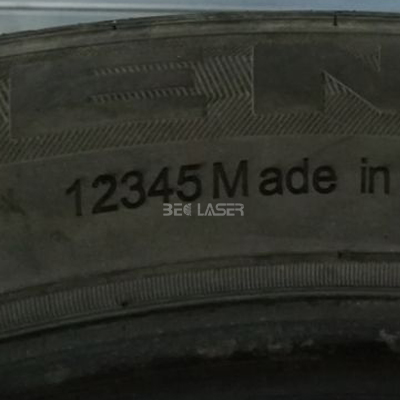

Rubber

Rubber is an ideal substrate for engraving or etching because it is soft and highly absorbent. However laser marking rubber does not offer contrast. Tires and handles are a few examples of markings done on rubber.

Each and every BEC Laser series is capable of marking on rubber and the ideal system for your application depends on your marking requirements. The only factors to consider are the speed and depth of the marking, as each laser series offers the same exact marking type. The more powerful the laser, the faster the engraving or etching process will be.

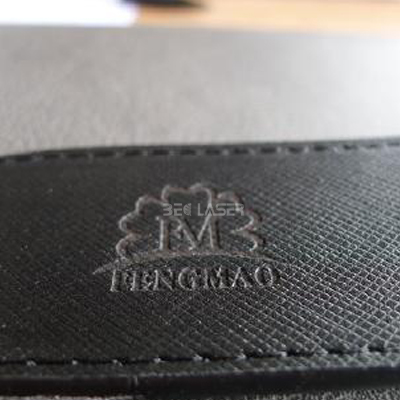

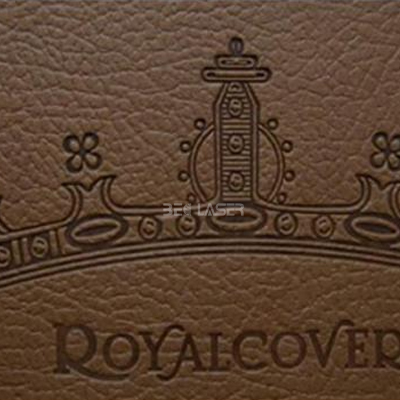

Leather

Leather is mainly used for shoe upper carving, handbags, leather gloves, luggage and so on. The production process includes perforation, surface engraving or cutting patterns, and the process requirements: the engraved surface does not turn yellow, the background color of the engraved material, the cutting edge of the leather is not black, and the engraving must be clear. The materials include synthetic leather, PU leather, PVC artificial leather, leather wool, semi-finished products, and various leather fabrics, etc.

In terms of leather products, the main technology of marking is reflected in the laser engraving of finished leather, laser perforating and engraving of leather shoes, laser marking of leather fabrics, engraving and perforating of leather bags, etc., and then different patterns created by laser to reflect exclusive leather Unique texture.