Laser Engraving & Cutting for Jewelry

More people are choosing to have their jewelry personalized with laser engraving. This is giving designers and stores specializing in jewelry the reason they need to invest in this modern technology. As a result, laser engraving is making significant inroads into the jewelry industry, with its ability to engrave almost any type of metal and the options it has to offer. Wedding and engagement rings, for example, can be made even more special by adding a message, date or an image that is meaningful to the buyer.

Laser engraving and laser marking can be used to inscribe personal messages and special dates on jewelry made from almost any metal. While traditional jewelry was made using gold, silver and platinum, modern jewelry designers use alternative metals such as tungsten, steel and titanium to create fashionable pieces. With the laser marking system manufactured by BEC LASER, it’s possible to add unique designs to any jewelry item for your customer, or to add a serial number or other identification mark to enable the owner to verify the item for security purposes. You can also add a vow to the inside of a wedding ring.

A laser engraving machine is a must-have for every manufacturer and vendor in the jewelry business. Engraving metals, jewelry, and other materials have been a very common practice from a long time back. But recently amazingly high-tech, laser engraving machines have been developed that can solve all your metallic and non-metallic marking problems.

Why Laser Engraving?

Laser engraving is a modern alternative to creating designs. Whether it is to create a classical style gold engraving, engrave rings, add a special inscription to a watch, decorate a necklace or to personalize a bracelet by engraving it, a laser offers you the opportunity to work on countless shapes and materials. Functional markings, patterns, textures, personalization and even photo-engravings can be achieved using a laser machine. It's a creative tool for a creative industry.

So what’s so special about laser engraving, and what’s the difference between this method and traditional engraving? Quite a bit, actually:

√ The laser provides clean, environmentally-friendly technology, which is chemical and residue free and doesn’t come into contact with the jewelry.

√ Laser technology gives the jeweler the chance to create exquisite designs with no risk to the item itself.

√ Laser engraving results in precise detail, which lasts longer than traditional engraving.

√ It’s possible to engrave text or graphics into the material at very specific depths.

√ Laser engraving is more effective on harder metals, it generally has a longer lifespan.

BEC Laser provides one of the best modern-day jewelry laser engraving machines that are precise and accurate with high robustness. It offers a non-contact, abrasion-resistant, permanent laser mark onto almost any type of material including gold, platinum, silver, brass, stainless steel, carbide, copper, titanium, aluminum as well as a wide variety of alloys and plastics.

Identification text, serial numbers, corporate logos, 2-D data matrix, bar coding, graphic and digital images, or any individual process data can be produced with laser engraving.

Higher powered laser engraving systems are also able to cut thin metals for creating monogram and name necklaces as well as other intricate design cutouts.

From brick and mortar jewelry stores to online shopping, retailers are offering name cutout necklaces for sale. These name necklaces are simple to make using advanced laser marking systems and laser marking software. The options available include: initials, monograms, first names and nicknames in the style or font of your choice.

Laser Cutting Machine for Jewelry

Jewelry designers and manufacturers are continually looking for reliable solutions for producing precision cutting of precious metals. Fiber laser cutting with high power levels, improved maintenance and better functionality is emerging as a top choice for jewelry cutting applications, particularly applications where superior edge quality, tight dimensional tolerances and high production is required.

Laser cutting systems can cut a wide variety of materials of varying thickness and are well suited for creating complex shapes. In addition, fiber lasers maximize precision, cut flexibility and throughput and offer a cost effective high accuracy cutting solution while at the same time providing jewelry designers freedom to create challenging shapes unconstrained by traditional cutting methods.

Laser cutting is the preferred method of making name cut outs and monogram necklaces. One of the most widely-used jewelry applications for lasers, cutting works by directing a high-powered laser beam at the sheet of metal chosen for the name. It traces the outline of the name in a font selected within the design software, and the material exposed is melted or burned away. The laser cutting systems are accurate to within 10 micrometers, which means the name is left with a high-quality edge and a smooth surface finish, ready for the jeweler to add loops for attaching a chain.

Name cut out pendants come in a variety of metals. Whether the customer chooses gold, silver, brass, copper, stainless steel or tungsten, laser cutting remains the most accurate method of creating the name. The range of options means this is a trend that isn’t exclusive to women; men typically prefer heavier metals and a bolder font, and jewelers generally try to accommodate all preferences. Stainless steel, for example, is popular with men because it has a slightly more casual feel about it, and laser cutting works better on the metal than any other fabrication method does.

The finish is vitally important for quality name cut outs, designs and monograms, and this is another reason why laser cutting is the first choice of most manufacturing jewelers. The lack of harsh chemicals means the base metal is undamaged by the process, and the clear-cut edge leaves the name cut out with a smooth surface ready for polishing. The polishing process depends on the metal selected and whether the customer wants a high-shine or a matte finish.

Below are just a few advantages of laser cutting machines compared to traditional cutting methods:

√ Minimal distortion on parts due to a small heat affected zone

√ Intricate part cutting

√ Narrow kerf widths

√ Very high repeatability

With a laser cutting system you can easily create complex cutting patterns for your jewelry designs:

√ Interlocking Monograms

√ Circle Monograms

√ Name Necklaces

√ Complex Custom Designs

√ Pendants & Charms

√ Intricate Patterns

If you want a high efficiency jewelry laser cutting machine, here recommend you BEC jewelry laser cutting machine.

Jewelry Laser Welding

During the last few years, the price of many jewelry laser welding machines has decreased, making them increasingly affordable to jewelry manufacturers, small design studios, repair shops and retail jewelers while offering additional features and flexibility to the user. Frequently, those who have purchased the jewelry laser welding machine find that the time, labor and material savings realized far outweigh the original purchase price.

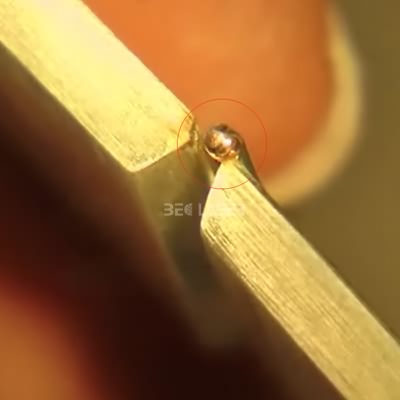

Jewelry laser welding can be used to fill porosity, re-tip platinum or gold prong settings, repair bezel settings, repair/resize rings and bracelets without removing stones and correct manufacturing defects. Laser welding reconfigures the molecular structure of either similar or dissimilar metals at the point of welding, allowing the two common alloys to become one.

Manufacturing and retail jewelers currently using laser welders are often amazed at the wide range of applications and the ability to produce a higher quality product in less time with fewer materials while eliminating excessive heat effects.

One of the key elements in making laser welding applicable to jewelry manufacturing and repair was the development of the “free-moving” concept. In this approach, the laser generates a stationary infrared light pulse which is targeted through the microscope’s cross-hair. The laser pulse can be controlled in size and intensity. Because the heat generated remains localized, operators can handle or fixture items with their fingers, laser welding small areas with pin-point accuracy without causing any harm to the operator’s fingers or hands. This free-moving concept enables users to eliminate costly fixturing devices and increase the range of jewelry assembly and repair applications.

Quick spot welds save bench workers a lot of fumbling. Lasers welders also allow designers to work more easily with difficult metals like platinum and silver, and to avoid accidentally heating and altering gemstones. The result is faster, cleaner work that bumps up the bottom line.

Most jewelers have some expectation of how a laser welder may or may not help with their jewelry business. After a short time with a laser, many companies say that the laser does much more than they originally thought it would. With the right machine and the right training, most jewelers will see a dramatic change in time and money spent on this new process.

Below is a short list of the benefits of laser welding:

√ Eliminates the need for solder materials

√ No more concerns about karat or color matching

√ Firescale and pickling are eliminated

√ Provide pinpoint accuracy for neat, clean laser welded joints

√ Laser weld spot diameter ranges from 0,05mm - 2,00mm

√ Optimal Output Pulse Shaping

√ Localized heat allows for “multi-pulsing” without damaging previous work

√ Small, mobile, powerful and easy to operate

√ Compact, self-contained water cooling system

Applications of the jewelry laser welding:

√ Repair most types of jewelry and eyeglass frames in minutes

√ Weld any size jewelry piece from large castings to tiny filigree wires

√ Resize rings and repair stone-settings

√ Completely assemble diamond tennis bracelets

√ Laser welding posts onto earring backs

√ Repair damaged jewelry pieces without removing stones

√ Repair/Refill porosity holes in castings

√ Repair/Reassemble eyeglass frames

√ Excellent for Titanium welding applications