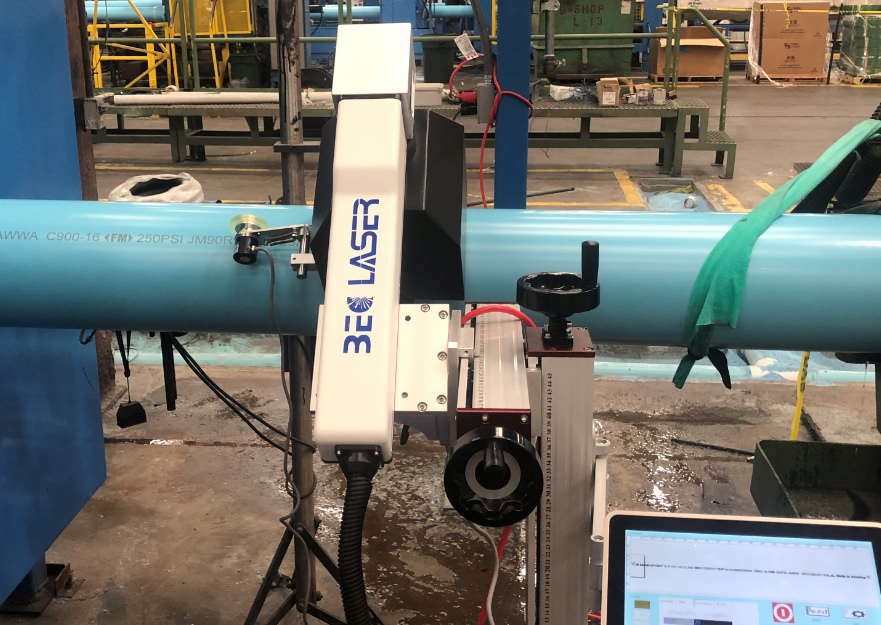

Laser Marking Machine for Pipe

Piping is a very important part of the building materials industry. Each pipeline has an identity code so that it can be inspected and tracked at any time, any time. The piping materials at each construction site are guaranteed to be authentic. Such permanent identification requires optical fibers. The laser marking machine is completed. Initially, most manufacturers used inkjet machines to mark the pipes, and now fiber laser marking machines are gradually replacing inkjet printers.

Why does laser marking machine replace inkjet machine?

The working principles of laser marking machines and inkjet printers are fundamentally different, just like new energy electric cars and traditional gasoline cars. The working principle of the laser marking machine is emitted by the laser light source. After the polarizer system burns on the product surface (physical and chemical reaction), traces will be left. It has the characteristics of green environmental protection, good anti-counterfeiting performance, non-tamperable, no consumption, long use time, high cost performance, and cost saving. No harmful chemicals such as ink are involved in the use process.

The working principle of the printer is that the ink channel is controlled by a circuit. After charging and high-voltage deflection, the ink line ejected from the nozzle forms characters on the surface of the product. It requires consumables such as ink, solvent, and cleaning agent, and the use cost is high. It needs maintenance during use, pollutes the environment, and is not friendly to the environment. You can refer to and compare the following two pictures:

Laser Marking Machine

The laser printer is the laser marking machine, which uses different lasers to strike the laser beam on the surface of various materials. The surface material is physically or chemically changed through light energy, thereby engraving patterns, trademarks and texts. Logo marking equipment.

Common laser marking machines include: fiber laser marking machine, carbon dioxide laser marking machine, ultraviolet laser marking machine; Among them, fiber laser marking machine and UV laser marking machine are suitable for pipelines.

Fiber laser marking machine and UV laser marking machine are used for pipes made of PVC, UPVC, CPVC, PE, HDPE, PP, PPR, PB, ABS and other materials.

PVC material most suitable marked by fiber laser.

PE material most suitable marked by UV laser .

Advantages of laser marking machine:

1. No consumables, long service life and low cost.

2. The laser marking machine can carry out shallow metal engraving, and it uses high-energy laser to make permanent marks on various metal and non-metal surfaces. The marking effect is corrosion-resistant and prevents malicious tampering.

3. High processing efficiency, computer control, easy to realize automation.

4. The laser marking machine has the advantages of no contact, no cutting force, little thermal influence, and will not damage the surface or interior of the printed object, ensuring the original accuracy of the workpiece.

5. The marking speed is fast, the computer-controlled laser beam can move at a high speed (5-7 m/s), the marking process can be completed in a few seconds, the effect is clear, long-term and beautiful.

6. A variety of options, with two-dimensional code software function option mode, can realize the focus adjustment of static marking or flying marking on the production line.

Reference drawing of pipe size, size and marking effect.