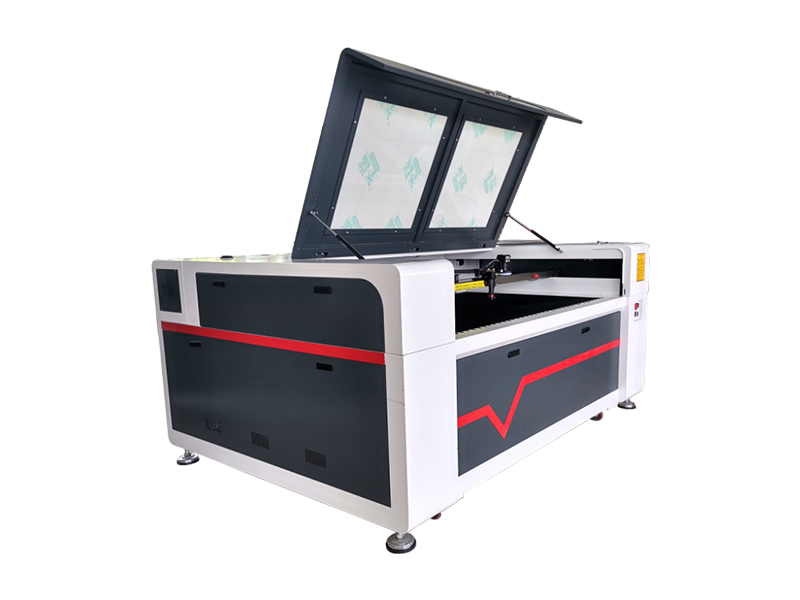

CO2 laser cutting machine is a cutting equipment used in industrial production.

Overview:

Non-metallic laser cutting machines generally rely on laser power to drive the laser tube to emit light, and through the refraction of several reflectors, the light It is transmitted to the laser head, and then the focusing mirror installed on the laser head gathers the light into a point, and this point can reach a very high temperature, so that the material is instantly sublimated into gas, which is sucked away by the exhaust fan, so as to achieve the purpose of cutting ; The main gas filled in the laser tube used by the general laser cutting machine is CO2, so this laser tube becomes a CO2 laser tube, and the laser cutting machine using this laser tube is called a CO2 laser cutting machine.

Model:

There are five models of CO2 cutters, each with a different power.

The first model: 4060, its working width is 400*600mm; its power has 60W and 80W options.

The second model: 6090, its working range is 600*900mm; its power has 80W and 100W options.

The third model: 1390, its working range is 900*1300mm, and the optional power is 80W/100W/130W and 160W.

The fourth model: 1610, its working range is 1000*1600mm, and the optional power is 80W/100W/130W and 160W.

The fifth model: 1810, its working range is 1000*1800mm, and the optional power is 80W/100W/130W and 160W.

Composition

It is mainly composed of four parts:

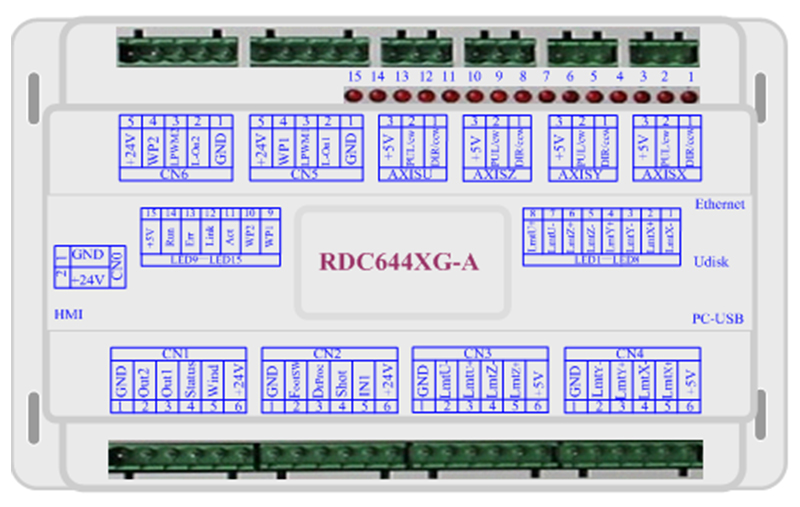

①Motherboard (RD motherboard)—- It is equivalent to the brain of the machine. It will process the instructions sent to it by the computer, and then control the laser power supply to supply the laser tube with electricity to make the laser tube emit light, and also control the movement of the plotter to complete the engraving work.

The Software is: RDWorks

Leetro motherboard

Software: Lasercut

②Plotter: It has two main functions, the optical transmission system and the instructions to complete the main board transmission, the optical transmission

It is transmitted from the light outlet of the laser tube to the laser head. Generally, there are three to four mirrors. The longer the path, the weaker the laser intensity.

The second is to complete the motherboard instructions to move to complete the engraving task

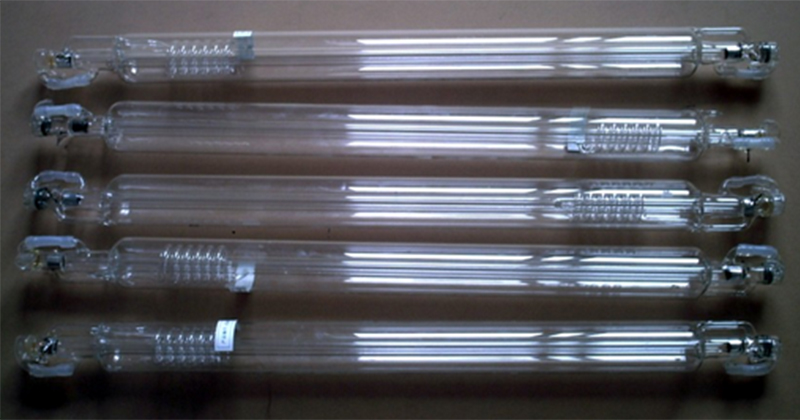

③Laser tube—glass tube

40-60w: 3 months warranty for ordinary laser tube

80-150w: Beijing EFR laser tube warranty 10 months EFR 9,000hour

80-150w:3 months warranty for ordinary laser tube

80-150w: Beijing heat stimulation light tube warranty 10 months RECI 9,000hour

④Laser power supply

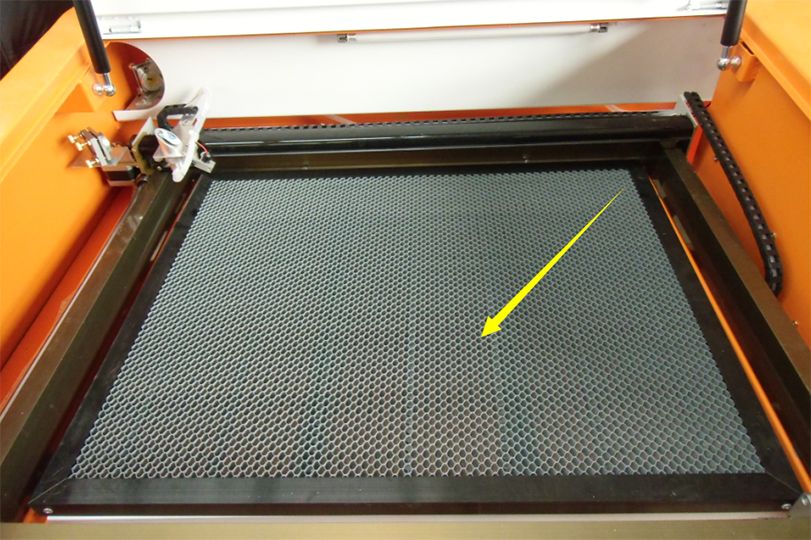

Worktable—–Adopt a cellular platform

Effect—–The main purpose of using a honeycomb workbench is to reduce the possibility of a solid surface workbench “fighting back”. If back reflection occurs, the back side of the material being processed is affected. Using a cellular workbench allows heat and beams to quickly leave the workbench without affecting other work areas. At the same time, it enhances the ability to deal with the smoke and debris generated by the laser cutting operation, keeps the work surface clean and tidy, and ensures the normal operation and function of the machine.

working principle—–The energy released when the laser beam is irradiated on The surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving, with high precision, fast speed, not limited to pattern restrictions, automatic typesetting to save materials, smooth cutting incision, The surface of the engraving is smooth, round, and the processing cost is low, which will gradually improve or replace the traditional cutting process equipment.

Advantages

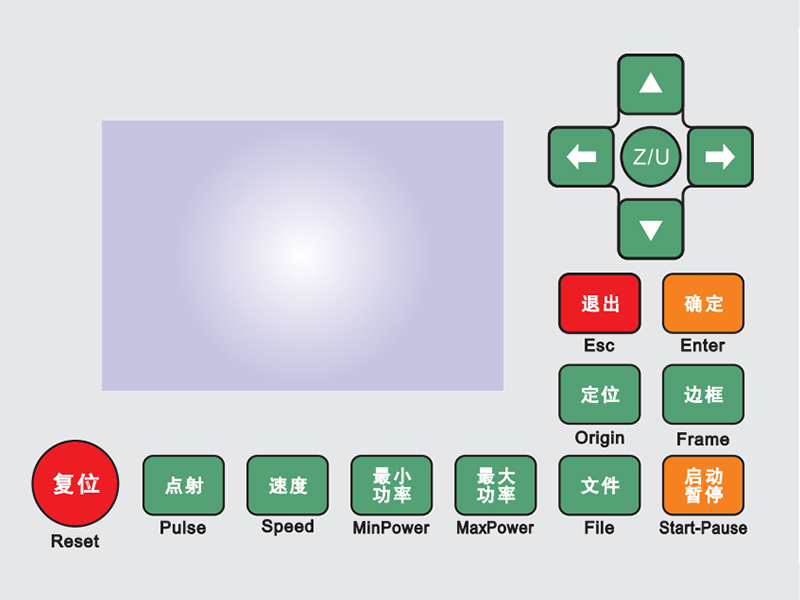

1. Support offline work (ie not connected to a computer to work)

2. Support multiple machines sharing one computer

3. Support USB cable transmission, U disk transmission, network cable transmission

4. Supports memory files, the fuselage can store tens of thousands of files, and it can work when called out

5. Support one-click repeat work, unlimited repeat work

6. Supports continuous engraving when power off

7. Support 256 layered output, different color layers can be set with different parameters, one output is completed

8.Support 24-hour uninterrupted high-intensity work

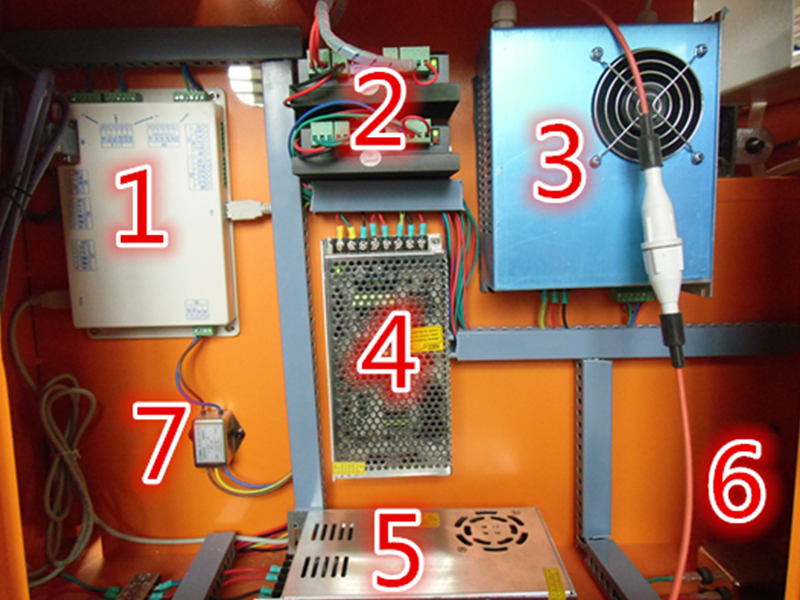

Laser engraving and cutting machine composition-internal composition

1、Motherboard

2、Drive (two)

3、Laser power supply

4、24V5V power supply

5、36V power supply

6、220v wave filter

7、24V wave filter

Industrial application

Cloth,leather,fur,acrylic,plastic glass,wooden board,plastic,rubber,bamboo,

product,resin and other non-metal materials

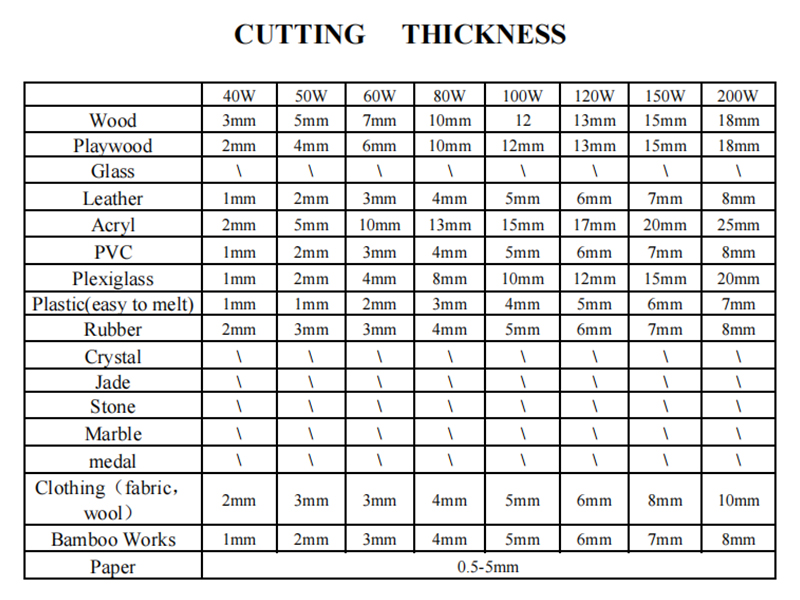

Technical parameter

Applicable materials

The cases suitable for CO2 laser cutting machines mainly include special parts that require uniform cutting, stainless steel with a thickness of no more than three millimeters and non-metallic materials with a thickness of no more than 20 millimeters used in advertising, decoration and other service industries。

Such as: Cloth, leather, fur, acrylic, glass, wooden board, plastic, rubber, bamboo, product, resin etc.

Machine Model

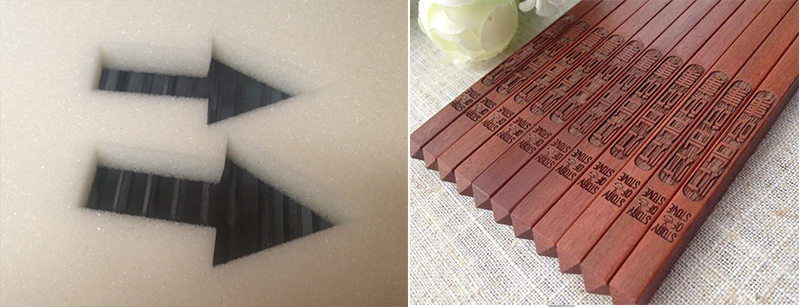

Samples

Routine maintenance

1. Circulating water

The circulating water is generally replaced once every 3-7 days. The water pump and water tank need to be cleaned once a week. Make sure that the circulating water is smooth before work. The quality and temperature of the circulating water directly affect the service life of the laser tube.

2. Fan cleaning

The long-term use of the fan will cause a lot of solid dust to accumulate in the fan, which will make the fan generate a lot of noise, and is not conducive to exhaust and deodorization. When the suction power of the fan is insufficient and the smoke exhaust is not smooth, first turn off the power, remove the air inlet and outlet ducts on the fan, remove the dust inside, then turn the fan upside down, and pull the fan blades inside until it is clean. , and then install the fan.

3: Inspection of the light path

The optical path system of the cutting machine is completed by the reflection of the mirror and the focusing of the focusing mirror. There is no offset problem of the focusing mirror in the optical path, but the three mirrors are fixed by the mechanical part and offset The possibility is high, although the deviation usually does not occur, but it is recommended that the user must check whether the optical path is normal before each work.

Post time: Apr-28-2023