In 3500 BC, the ancient Egyptians first invented glass. Since then, in the long river of history, glass will always appear in both production and technology or daily life. In modern times, various fancy glass products have emerged one after another, and the glass manufacturing process is also constantly improving.

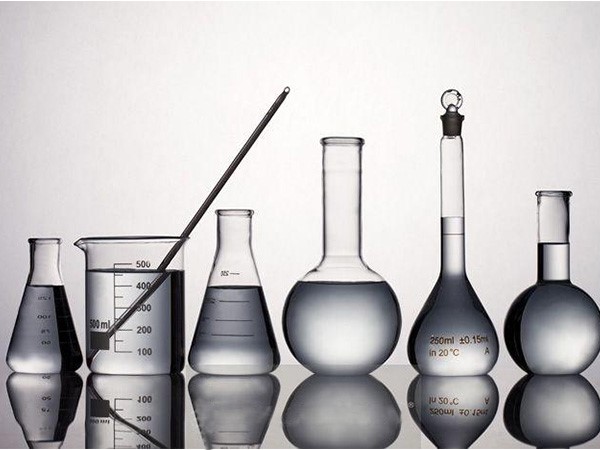

Glass is often used in the medical research and development industry due to its high transparency and good light transmittance, such as common test tubes, flasks, and utensils. It is also often used for packaging due to its high chemical stability and good airtightness. drug. While glass is widely used, the demand for glass marking and lettering derived from it has gradually attracted people’s attention.

Common engraving on glass includes: decorative engraving method, that is, the use of chemical agents-etchant to corrode and engrave glass, manual knife engraving, physical engraving on the glass surface with a special engraving knife, and a laser marking machine engraving.

Why is glass marking difficult?

As we all know, glass has a shortcoming, that is, it is a fragile product. Therefore, if the process is difficult to grasp this degree during glass processing, improper processing will cause the material to be scrapped. Although the laser can perform fine processing of a variety of materials, but if the laser is selected or used improperly, it will still cause difficult processing.

This is because when the laser is incident on the glass, part of the light will be reflected on the surface, and the other part will be directly transmitted through. When laser marking on the glass surface, a strong energy density is required, but if the energy density is too high, cracks or even chipping will occur; and if the energy density is too low, it will cause the dots to sink or cannot be etched directly on the surface. It can be seen that even using lasers to process glass is difficult.

How to solve the problem of glass marking?

To solve this problem, specific analysis of specific problems is needed. The marking of glass surface can be divided into marking on curved glass surface and marking on flat glass surface.

-Curved glass marking

Influencing factors: The processing of curved glass will be affected by the curved surface. The peak power of the laser, the scanning method and speed of the galvanometer, the final focus spot, the focal depth of the spot and the scene range will all affect the processing of the curved glass.

Specific performance: Especially during processing, you will find that the processing effect of the glass edge is extremely poor, or even no effect at all. This is because the focal depth of the light spot is too shallow.

M², spot size, field lens, etc. will affect the depth of focus. Therefore, a laser with good beam quality and narrow pulse width should be selected.

-Flat glass marking

Influencing factors: peak power, final focused spot size, and galvanometer speed will directly affect the surface processing of flat glass.

Specific performance: The most common problem in its processing is that when ordinary lasers are used for flat glass marking, there may be etching through the glass. This is because the peak power is too low and the energy density is not concentrated enough.

Peak power is affected by pulse width and frequency. The narrower the pulse width, the lower the frequency and the higher the peak power. The energy density is affected by the beam quality M2 and the spot size.

Summary: It is not difficult to see that whether it is flat glass or curved glass, lasers with better peak power and M2 parameters should be selected, which can effectively improve the efficiency of glass marking processing.

What is the best laser for glass marking?

Ultraviolet lasers have natural advantages in the glass processing industry. Its short wavelength, narrow pulse width, concentrated energy, high resolution, fast speed of light, it can directly destroy the chemical bonds of substances, so that it can be cold processed without heating the outside, and there will be no deformation of graphics and black fonts after processing. It greatly reduces the appearance of defective products in the mass production of glass marking and avoids the waste of resources.

The main marking effect of the UV laser marking machine is to directly break the molecular chain of the substance through the short-wavelength laser (different from the evaporation of the surface substance produced by the long-wave laser to expose the deep substance) to reveal the pattern and text to be etched. The focusing spot is extremely small, which can reduce the mechanical deformation of the material to a large extent and has little processing heat influence, which is especially suitable for glass carving.

Therefore, BEC UV laser marking machine is an ideal tool for processing fragile materials and has been widely used in the field of glass marking. Its laser-marked patterns, etc., can reach the micron level, which is of great significance for product anti-counterfeiting.

Post time: Aug-03-2021