Introduction to Laser Cleaning System The traditional cleaning industry has various cleaning methods, mostly using chemical agents and mechanical methods for cleaning. In today’s increasingly stringent environmental protection regulations and people’s increasing awareness of environmental protection and safety, the types of chemicals that can be used in industrial cleaning will become less and less. How to find a cleaner and non-destructive cleaning method is a problem we have to consider. Laser cleaning has the characteristics of no grinding, non-contact, no thermal effect, and is suitable for objects of various materials, and is considered to be an effective solution.

Laser cleaning machine is a new generation of high-tech products for surface cleaning. Easy to install, operate and automate. Simple operation, turn on the power and turn on the equipment, you can clean without chemical reagents, medium, and water. It has the advantages of manually adjusting the focus, cleaning with curved surfaces, and cleaning the surface cleanliness. Stains, dirt, rust, coatings, plating, paint, etc.

1.Features

1) Non-contact cleaning, no damage to the parts matrix.

2) Precise cleaning, which can achieve selective cleaning of precise location and precise size.

3) No chemical cleaning solution, no consumables, safe and environmentally friendly

4) The operation is simple, it can be powered on, and it can be hand-held or cooperated with a manipulator to realize automatic cleaning.

5) The cleaning efficiency is very high, saving time.

6)The laser cleaning system is stable and requires almost no maintenance.

2.Application

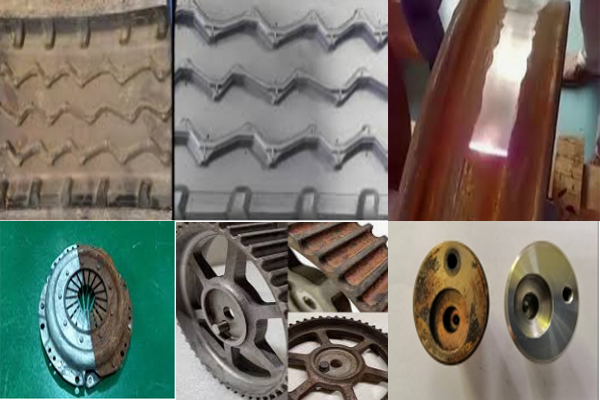

Laser cleaning is widely used in various industries, such as: shipbuilding, auto parts, rubber molds, machine tools, tire molds, rails, environmental protection industries and other industries.

In the field of industrial applications, laser cleaning objects are divided into two parts: substrates and cleaning objects. The substrates mainly include surface contamination layers of various metals, semiconductor wafers, ceramics, magnetic materials, plastics and optical components. The cleaning objects mainly include surface In the industrial field, it is widely used in rust removal, paint removal, oil removal, film removal/oxidation removal, and resin, glue, dust and slag removal.

3.Cleaning application of laser cleaning machine in the automotive industry

Traditional cleaning methods are time-consuming, cannot be automated, and often have a detrimental impact on the environment. The fast, automated nature of laser cleaning allows for thorough cleaning of surface residues, resulting in strong, void- and micro-crack-free welds and bonds. In addition, laser cleaning is gentle and the process is significantly faster than other methods, advantages that have been recognized by the automotive industry. In the industrial field, in order to protect metal or other substrate materials, the surface is generally painted to prevent rust, oxidation, and corrosion. When the paint layer is partially peeled off or the surface needs to be repainted for other reasons, the original paint layer needs to be completely cleaned.

Selective paint stripping is one of the many applications of laser cleaning, often the top weathered coating on a vehicle needs to be thoroughly removed before new paint can be applied. Since the physical and chemical properties of the top layer of paint are different from the primer, the power and frequency of the laser can be set to remove only the top layer of paint.

Laser cleaning machine is very effective in situations where critical welds on painted structural parts must be removed for inspection. Lasers can remove coatings without the need for hand or power tools, abrasives or chemicals that can hide problem areas and cause further damage to the surface. Wuhan Ruifeng Optoelectronics Laser is one of the first batch of laser equipment companies. With more than ten years of R&D and production experience, it leads the industry in terms of technology and integration. Since its establishment, the company has always paid attention to the research and development of laser technology and the development needs of customers, and is committed to providing perfect material processing solutions for each enterprise.

Post time: Jun-28-2023