Laser welding is a welding technique used to join multiple pieces of metal through the use of a laser beam. The laser welding system provides a concentrated heat source, allowing for narrow, deep welds and high welding rates. This process is used frequently in high volume welding applications, such as in the Automotive Industry.

Laser welding speeds up the process of replacing forged parts with stamped parts. Laser welding is used to replace discrete spot welds with continuous laser welds, which can reduce the overlap width and some strengthening parts, and can compress the volume of the body structure itself. As a result, the weight of the vehicle body can be reduced by 56kg. The application of laser welding has achieved weight reduction and emission reduction, which meets the requirements of environmental protection in today’s era.

Laser welding is applied to tailor welding of unequal thickness plates, and the benefits are more significant. This technology transforms the traditional manufacturing process-first stamping into parts, and then spot welding into a whole-into: first welding several parts with different thicknesses into a whole, and then stamping and forming, reducing the number of parts and using more materials. Reasonable, the structure and function are significantly improved.

Different laser welding methods are often used for welding of different body parts. The following is a list of several laser welding methods commonly used in the automotive industry.

(1) Laser brazing

Laser brazing is mostly used for the connection of the top cover and the side wall, trunk lid, etc. Volkswagen, Audi, Peugeot, Ford, Fiat, Cadillac, etc. all use this welding method.

(2) Laser self-fusion welding

Laser self-fusion welding belongs to deep penetration welding, which is mainly used for roof and side panels, car doors, etc. At present, many brand cars of Volkswagen, Ford, GM, Volvo and other manufacturers use laser self-fusion welding.

(3) Laser remote welding

Laser remote welding uses robot + galvanometer, remote beam positioning + welding, and its advantage lies in greatly shortening the positioning time and higher efficiency compared with traditional laser processing.

Laser welding can also be applied to cigar lighter ,valve lifters, cylinder gaskets, fuel injectors, spark plugs, gears, side shafts, drive shafts, radiators, clutches, engine exhaust pipes, supercharger axles, and airbag liner repair and splicing of damaged auto parts.

Laser welding has numerous advantages and benefits over traditional welding methods and can greatly reduce costs while improving production efficiency and quality.

Laser welding has the following characteristics:

①Narrow heating range (concentrated).

②The action area and position are precisely controllable.

③The heat-affected zone is small.

④The welding deformation is small, and no post-welding correction is required.

⑤ Non-contact processing, no need to pressurize the workpiece and surface treatment.

⑥It can realize the welding of dissimilar materials.

⑦The welding speed is fast.

⑧No thermal influence, no noise and no pollution to the outside world.

The recommended machines suitable for welding auto are as follows:

Laser welding Machine for Mold

With the development of the industry, laser welding technology is constantly researched and innovated. At present, in the mechanical welding industry, the popular laser welding machine is due to its outstanding performance characteristics and shows good process characteristics during the welding process. So it can be widely used in many fields.

The mold in mold laser welding plays an extremely important role in modern industry, and its quality directly determines the quality of the product. Improving the service life and accuracy of molds and shortening the manufacturing cycle of molds are technical problems that many companies urgently need to solve. However, failure modes such as collapse, deformation, wear, and even breakage often occur during the use of molds. Therefore, laser welding repair technology is also necessary for mold repair.

Laser welding machine is a new type of welding method, mainly for the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, and heat-affected zone. Small, small deformation, fast welding speed, smooth and beautiful welding seam, no need or simple processing after welding, high welding seam quality, no air holes, precise control, small focus spot, high positioning accuracy, and easy to realize automation.

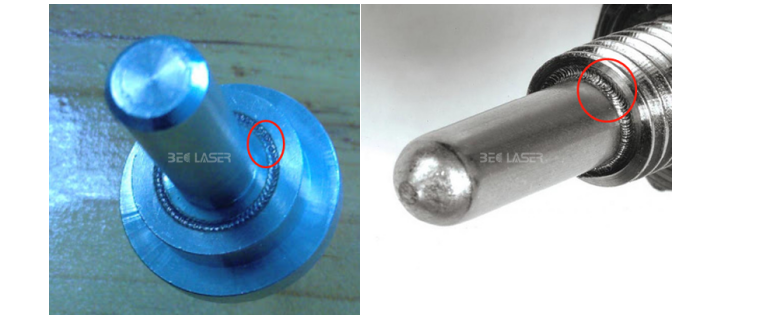

A typical example of the application of laser welding in the mold industry is the mold repair laser welding machine. This equipment is easy for operators to use, can greatly increase the speed of welding repair, and the repair effect and precision are close to beautiful, which makes the equipment It is widely used in the field of mold welding. The repair welding heat affected area of this welding machine is very small, and it does not need to be heated in advance, and the welded workpiece does not appear annealing phenomenon after work. This laser welding repair technology can not only be used to repair mold wear, but also can achieve precise welding of different body parts.

Post time: Jul-15-2021