In recent years, the application of pulsed fiber lasers in the field of laser marking has developed rapidly, among which applications in the fields of electronic 3C products, machinery, food, packaging, etc. have been very extensive.

Currently, the types of pulsed fiber lasers used in laser marking on the market mainly include Q-switched technology and MOPA technology. MOPA (Master Oscillator Power-Amplifier) laser refers to a laser structure in which a laser oscillator and an amplifier are cascaded. In the industry, MOPA laser refers to a unique and more “intelligent” nanosecond pulse fiber laser composed of a semiconductor laser seed source driven by electric pulses and a fiber amplifier. Its “intelligence” is mainly reflected in the output pulse width is independently adjustable (range 2ns-500ns), and the repetition frequency can be as high as megahertz. The seed source structure of the Q-switched fiber laser is to insert a loss modulator in the fiber oscillator cavity, which generates a nanosecond pulse light output with a certain pulse width by periodically modulating the optical loss in the cavity.

The internal structure of the laser

The internal structure difference between MOPA fiber laser and Q-switched fiber laser mainly lies in the different generation methods of pulse seed light signal. The MOPA fiber laser pulse seed optical signal is generated by the electric pulse driving semiconductor laser chip, that is, the output optical signal is modulated by the driving electric signal, so it is very strong for generating different pulse parameters (pulse width, repetition frequency, pulse waveform and power, etc.) Flexibility. The pulse seed optical signal of the Q-switched fiber laser generates pulsed light output by periodically increasing or reducing the optical loss in the resonant cavity, with a simple structure and a price advantage. However, due to the influence of Q-switching devices, the pulse parameters have certain restrictions.

Output optical parameters

MOPA fiber laser output pulse width is independently adjustable. The pulse width of MOPA fiber laser has any tunability (range 2ns~500 ns). The narrower the pulse width, the smaller the heat-affected zone, and higher processing accuracy can be obtained. The output pulse width of the Q-switched fiber laser is not adjustable, and the pulse width is generally constant at a certain fixed value between 80 ns and 140 ns. MOPA fiber laser has a wider repetition frequency range. The re-frequency of MOPA laser can reach the high frequency output of MHz. High repetition frequency means high processing efficiency, and MOPA can still maintain high peak power characteristics under high repetition frequency conditions. The Q-switched fiber laser is limited by the working conditions of the Q switch, so the output frequency range is narrow, and the high frequency can only reach ~100 kHz.

Application scenario

MOPA fiber laser has a wide parameter adjustment range. Therefore, in addition to covering the processing applications of conventional nanosecond lasers, it can also use its unique narrow pulse width, high repetition frequency, and high peak power to achieve some unique precision processing applications. such as:

1.Application of surface stripping of aluminum oxide sheet

Today’s electronic products are becoming thinner and lighter. Many mobile phones, tablets, and computers use thin and light aluminum oxide as the product shell. When using a Q-switched laser to mark conductive positions on a thin aluminum plate, it is easy to cause deformation of the material, resulting in “convex hulls” on the back, directly affecting the aesthetics of the appearance. The use of the MOPA laser’s smaller pulse width parameters can make the material not easy to deform, and the shading is more delicate and brighter. This is because the MOPA laser uses a small pulse width parameter to make the laser stay on the material shorter, and it has high enough energy to remove the anode layer, so for the processing of stripping the anode on the surface of the thin aluminum oxide plate, MOPA Lasers are a better choice.

2.Anodized aluminum blackening application

Using lasers to mark black trademarks, models, texts, etc. on the surface of anodized aluminum materials, instead of traditional inkjet and silk screen technology, it has been widely used on the shells of electronic digital products.

Because the MOPA pulsed fiber laser has a wide pulse width and repetition frequency adjustment range, the use of narrow pulse width and high frequency parameters can mark the surface of the material with a black effect. Different combinations of parameters can also mark different gray levels. effect.

Therefore, it has more selectivity for the process effects of different blackness and hand feeling, and it is the preferred light source for blackening anodized aluminum on the market. Marking is carried out in two modes: dot mode and adjusted dot power. By adjusting the density of dots, different grayscale effects can be simulated, and customized photos and personalized crafts can be marked on the surface of anodized aluminum material.

3.Color laser marking

In the stainless steel color application, the laser is required to work with small and medium pulse widths and high frequencies. The color change is mainly affected by frequency and power. The difference in these colors is mainly affected by the single pulse energy of the laser itself and the overlap rate of its spot on the material. Because the pulse width and frequency of the MOPA laser are independently adjustable, adjusting one of them will not affect the other parameters. They cooperate with each other to achieve a variety of possibilities, which cannot be achieved by a Q-switched laser. In practical applications, by adjusting the pulse width, frequency, power, speed, filling method, filling spacing and other parameters, permuting and combining different parameters, you can mark more of its color effects, rich and delicate colors. On stainless steel tableware, medical equipment and handicrafts, gorgeous logos or patterns can be marked to play a beautiful decorative effect.

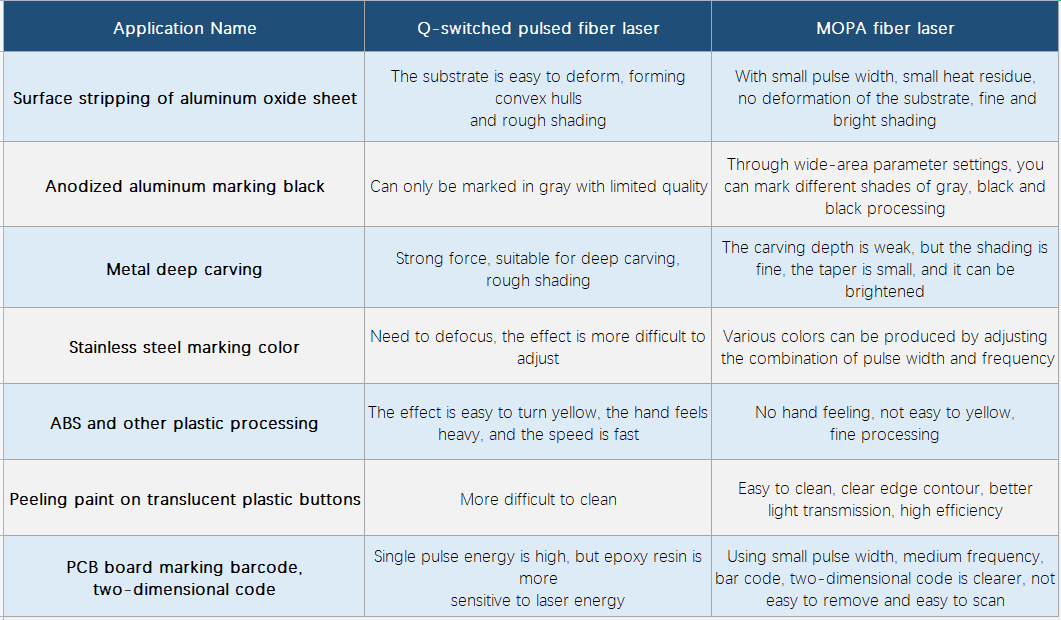

In general, the pulse width and frequency of the MOPA fiber laser are independently adjustable, and the adjustment parameter range is large, so the processing is fine, the thermal effect is low, and it has outstanding advantages in aluminum oxide sheet marking, anodized aluminum blackening, and stainless steel coloring. Realize the effect that Q-switched fiber laser cannot achieve The Q-switched fiber laser is characterized by strong marking power, which has certain advantages in deep engraving processing of metals, but the marking effect is relatively rough. In common marking applications, MOPA pulsed fiber lasers are compared with Q-switched fiber lasers, and their main features are shown in the following table. Users can choose the right laser according to the actual needs of marking materials and effects.

MOPA fiber laser pulse width and frequency are independently adjustable, and the adjustment parameter range is large, so the processing is fine, the thermal effect is low, and it has outstanding advantages in aluminum oxide sheet marking, anodized aluminum blackening, stainless steel coloring, and sheet metal welding. The effect that Q-switched fiber laser cannot achieve. The Q-switched fiber laser is characterized by strong marking power, which has certain advantages in deep engraving processing of metals, but the marking effect is relatively rough.

In general, MOPA fiber lasers can almost replace Q-switched fiber lasers in laser high-end marking and welding applications. In the future, the development of MOPA fiber lasers will take narrower pulse widths and higher frequencies as the direction, and at the same time march towards higher power and higher energy, continue to meet the new requirements of laser material fine processing, and continue to develop such as laser derusting and lidar. And other new application areas.

Post time: Jul-18-2021