For medical device manufacturers, marking medical devices may be a big challenge. Identification tasks are becoming more and more demanding, and industry regulations are becoming more and more stringent, such as the UDI (Unique Device Identification) directive of the FDA (U.S. Food and Drug Administration).

Medical products escort our health. Due to the special nature of medical products, medical products have strict quality standards and are very concerned about the health and safety during processing. Therefore, the marking requirements for medical products are very high. Conventional spray marking methods often involve the use of poisoning and environmentally harmful substances, so that it often cannot be used for marking.

The production standards for medical products are very strict,such as the UDI (Unique Device Identification) directive of the FDA (U.S. Food and Drug Administration).. The key components need to be marked with permanent and traceable marks. Through this mark, you can find the production time, location, production batch number, manufacturer and other information of the product.

Moreover, in the medical industry, the safety and hygiene of products are very important, and the ultra-short pulse laser marking technology has the advantages of cold processing, low energy consumption, small damage, high accuracy, strict positioning in 3D space, smooth marking surface and not easy to breed bacteria. It fully meets the requirements of the medical industry for marking medical products.

Traceability is one of the essential requirements of the medical sector. Precision is another. Laser medical marking fulfils this and other requirements. It is the preferred method for product identification marks on medical devices such as orthopedic implants, medical supplies and other medical instruments because the marks are corrosion resistant and withstand sterilization processes such as, passivation, centrifuging, and autoclaving.

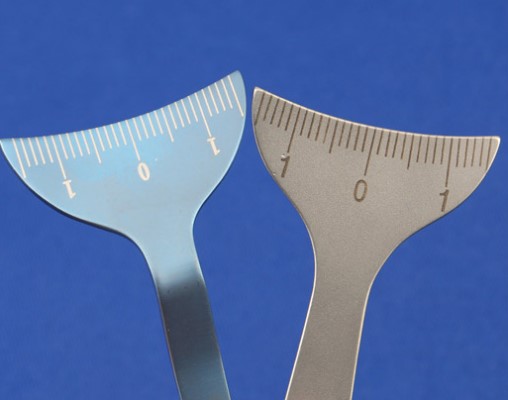

When it comes to medical device identification and marking, precision is crucial. Some medical devices, implants and surgical instruments continue to become smaller and more efficient, laser marking systems are able to meet very high quality standards, along with strict identification and traceability guidelines provided by the government for product identification. Fiber laser engraving and marking systems are capable of direct part marking and engraving bar codes, lot numbers and date codes that conform to most manufacturing standards, including government regulations for adding Unique Identification Marking or UDI markings.

UDI Laser Marking: UDI or Unique Device Identification requires some types of medical devices and packaging to be marked with information such as date codes, batch numbers, expiry dates and serial numbers. Laser marking provides the most reliable direct part marking available, providing the high contrast details to ensure maximum traceability. BEC Laser offer a wide range of laser marking solutions for the contamination-free, non-distorting, indelible marking.

Laser marking is a marking method that uses a high-energy-density laser to locally illuminate a workpiece to vaporize the surface material, thereby leaving a permanent mark. At the same time of processing, there is no need to contact the surface of the processed article, no mechanical extrusion and mechanical effects, no cutting force, little thermal influence, and the original precision of the medical product is guaranteed.

At the same time, it has a wide range of applications, and it can mark most metal materials and non-metals, and the marking is durable and not easy to wear, which greatly meets the marking requirements of the materiality of medical products.

Compared with the traditional medical marking method, the laser marking technology not only has more flexible operation, but also has higher reliability and more space for creation.

Post time: Apr-14-2021