Logo is an important feature that reflects a good product, such as food packaging, with logo, production date, place of origin, raw materials, barcodes, etc., allowing consumers to better understand this product and increase consumption when buying The confidence of the readers can also improve the brand’s popularity. So how are these packaging graphics formed? What effect can it have on anti-counterfeiting? Let’s analyze it together.

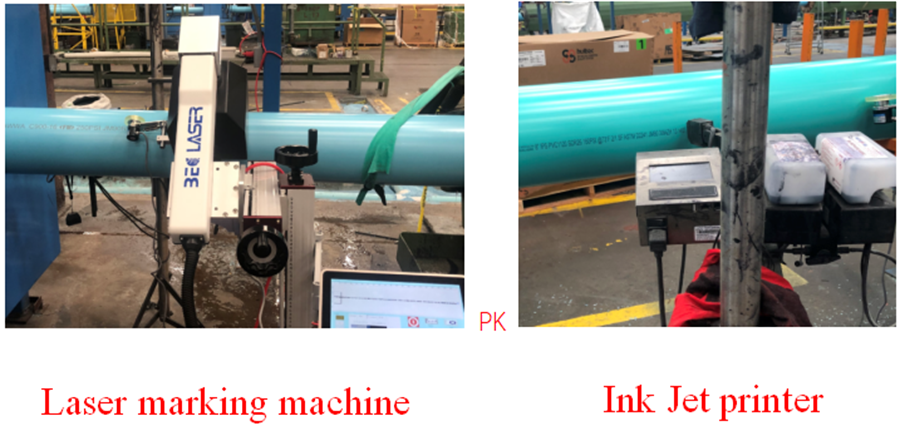

At present, most of the text patterns of many packaging or product parts on the market use inkjet marking or laser marking. The former is widely used, while laser marking has become more sophisticated in recent years. A marking method that is becoming popular. Faced with these two marking methods, many people have questions. Which product to choose for marking? What is the difference between laser marking and inkjet marking? Why is laser marking an upgrade of inkjet marking?

First of all, we first understand what is ink jet printer and laser marking machine

The principle of the inkjet printer is: the nozzle is composed of multiple high-precision valves. When printing characters, the ink is ejected by a constant internal pressure to form characters or graphics on the moving surface.

As an early inkjet printer, there are four major problems that cannot be overcome: high pollution, high consumables, high failures, and high maintenance.

In particular, the chemical pollution generated when it is in use can cause damage to the environment and operators. Hurt, and gradually fail to keep up with the pace of industry development.

1. The ink and solvent used in the inkjet printer are highly volatile substances, which will produce more chemical toxic residues and pollute the environment.

2. The ink jet coding equipment consumes a large amount of special ink, consumes a large amount of consumables, and costs too much.

3. The printer will block the print head due to the change of environmental temperature, humidity and dust, and the failure rate is high.

4. The replacement of nozzles and other accessories is expensive and requires professional maintenance personnel.

Laser marking machine

Laser marking technology is a more advanced technology than ink jet coding technology. The application of laser marking machines in the Chinese market has just begun, but the development trend is rapid. The laser marking machine greatly improves the problems existing in the traditional coding machine, improves the reliability and flexibility of the equipment, and is suitable for various metal and non-metal materials.

The working principle of the laser marking machine is to concentrate the laser on the surface of the object to be marked with a very high energy density, in a very short time, vaporize the material on the surface, and control the effective displacement of the laser beam to accurately Exquisite patterns or text are carved out, so laser marking is the greenest and safest marking equipment.

The advantages of laser marking machine are mainly as follows:

1. Reduce production costs, reduce consumables, and improve production efficiency;

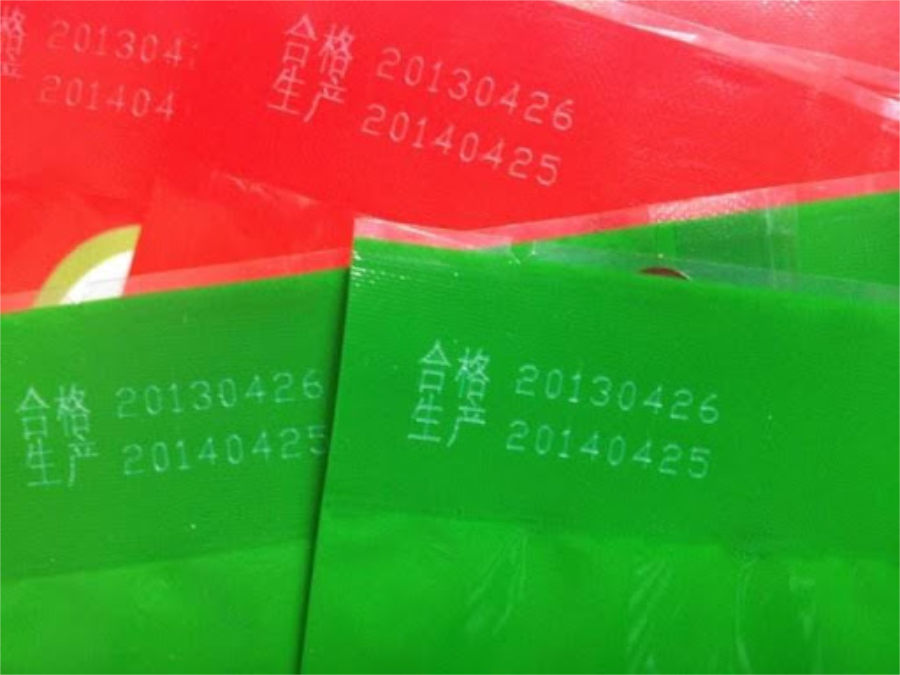

2. The anti-counterfeiting effect is obvious, and the laser marking technology can effectively inhibit the counterfeiting of product identification;

3. It is conducive to product tracking and recording. The laser marking machine can print the batch number and production date of the product, which can make each product have a good tracking performance;

4. Increasing the added value can make the product look higher grade and enhance the brand awareness of the product;

5. The equipment is reliable. The laser marking (marking) machine has a mature industrial design, stable and reliable performance, and can work continuously for 24 hours. It is widely used in the production line of various LED industries;

6. Environmental protection and safety. The laser marking machine does not produce any chemical substances harmful to the human body and the environment.

This is the reason for the rapid development of laser marking machines.

Post time: Oct-18-2021