In recent years, the development of the manufacturing industry has been very rapid, and the demand for metal processing has also increased. Welding is one of the important processes of metal processing, and traditional welding methods have been unable to meet the needs of production. Under this premise, the hand-held laser welding machine was born, which was widely praised once it was launched, and quickly replaced the traditional welding thin plate welding market.

The hand-held fiber laser welding machine is a new generation of laser welding equipment. It belongs to non-contact welding. It does not require pressure during the operation. , which melts the material inside, and then cools and crystallizes to form a weld.

a. No external force will be exerted on the workpiece

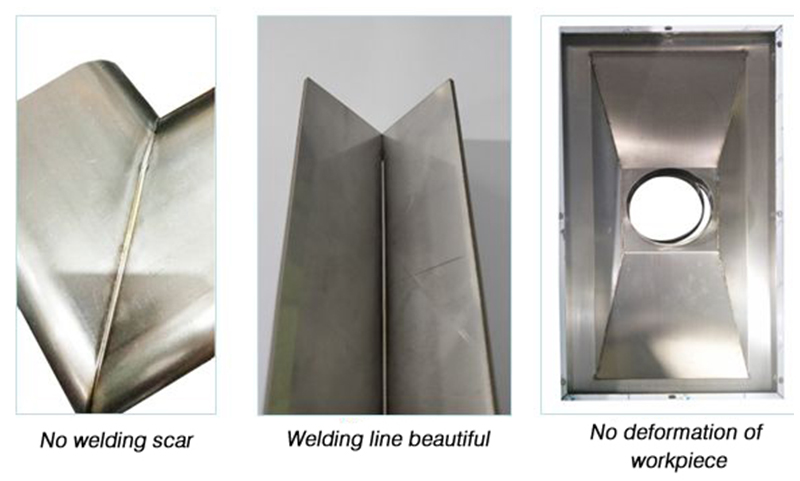

When the hand-held laser welding machine processes the parts, since it will not come into contact with the processed parts, there will be no external stress on the processed parts during the whole welding process, and the energy concentration generated by the laser is very high. The thermal influence on the surrounding of the part is relatively small, so the part will not be deformed during welding.

b. Welding between dissimilar materials can be realized

In the traditional welding process, usually only two workpieces made of the same material can be welded, but the laser welding process of the advanced hand-held laser welding machine can not only weld high melting point and various materials that are difficult to melt and weld, Such as titanium alloy, aluminum alloy and other materials. In addition, the laser welding processing technology can also realize the welding between some dissimilar materials, breaking through the welding limitation between materials.

c. Narrow welding seam, neat and beautiful appearance

The laser welding technology of the hand-held laser welding machine is very advanced, not only does not pollute the environment, but also forms small solder joints, narrow welding seams, uniform welding seam structure, very few pores and defects, which can reduce and optimize the parent material impurities, Therefore, after welding, not only various resistances are excellent, but the surface of the material is also very neat and beautiful.

Features of hand-held laser welding machine:

1. The device is small in size

2. Flexible and convenient operation, can realize outdoor welding

3. Good beam quality, fast speed, small thermal deformation, precision and high integration

4. The welding seam is beautiful, flat and free of pores, and no treatment or simple treatment is required after welding.

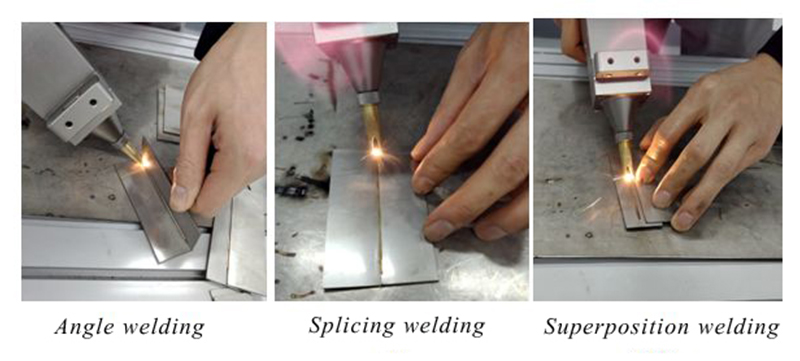

5. The hand-held welding gun can weld the workpiece at any angle, which is suitable for the spot welding of complex welds and various devices.

Advantages of hand-held laser welding machine:

1. The operation is simple and easy to use: the hand-held laser welding machine is easy to operate and has low labor costs.

2. Fast welding speed: The hand-held laser welding machine is continuous welding, the beam energy is dense, the welding is efficient and high-speed, the welding spot is small, the heat affected area is small, the welding seam is smooth and beautiful, and the subsequent grinding process is reduced.

3. Various welding materials: The hand-held laser welding machine can weld common metal materials such as stainless steel plates, iron plates, galvanized plates, and aluminum plates.

4. Low processing environment requirements: The hand-held laser welding machine does not require a special welding table, the equipment occupies a small space, and the processing is flexible. It is equipped with several meters of optical fiber extension lines, which can be moved for long-distance operations without environmental space restrictions.

5. Sustainable work: The laser is equipped with water cooling equipment, which can ensure continuous high-intensity work.

6. High cost performance: The hand-held laser welding machine can not only perform welding operations, but also repair molds. The life of the laser is 100,000 hours, which is much longer than the service life of ordinary equipment, and it is cost-effective.

Comparison of energy consumption between hand-held laser welding machine and argon arc welding:

Compared with traditional arc welding, the hand-held laser welding machine saves about 80% to 90% of electric energy, and the processing cost can be reduced by about 30%. Welding effect comparison: hand-held laser welding machine can complete dissimilar steel and dissimilar metal welding. Fast speed, small deformation and small heat affected zone. The welds are beautiful, flat, and have no/less porosity. Hand-held laser welder for tiny open parts and welding. Subsequent process comparison: The hand-held laser welding machine has low heat input and small deformation of the workpiece during welding, and can obtain a beautiful welding surface without or only simple treatment (depending on the welding surface effect requirements). The hand-held laser welding machine can greatly reduce the labor cost of the huge polishing and leveling process.

Application fields of hand-held laser welding machine:

Mainly for the fixed position of large and medium-sized sheet metal, cabinet, chassis, aluminum alloy door and window frame, stainless steel wash basin and other large workpieces such as inner right angle, outer right angle, plane weld welding, small heat affected area during welding, small deformation, and welding depth Large and solidly welded. Widely used in kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel product industry, stainless steel engineering industry, door and window industry, handicraft industry, household products industry, furniture industry, auto parts industry, etc.

The application and intelligence of laser welding machines have become a powerful equipment in industrial equipment. The superior processing performance and excellent processing characteristics of hand-held laser welding machines have created high contributions to the production of major enterprises. , is also the choice of more and more processing plants.

Post time: May-10-2023