Fiber Laser Welding Machine-Handheld Type

Product Introduction

The working mode of hand-held fiber laser welding machine, hand-held welding is flexible and convenient, and the welding distance is longer. Using a handheld welding gun to replace the previous fixed light path has the advantages of simple operation, beautiful welding seams, fast welding speed and no consumables.

For welding thin stainless steel plates, iron plates, galvanized plates and other metal materials, it can perfectly replace traditional argon arc welding, electric welding and other processes. Hand-held fiber laser welding machine is mainly used for laser welding of long-distance and large workpieces. The heat-affected area is small during welding, and it will not cause work deformation, blackening, and traces on the back. The welding depth is large, the welding is firm, and the melting is sufficient. There is no dent on the convex part of the molten material in the melting pool and the substrate.

Handheld Fiber laser welding machine is a laser welding equipment which couples the high energy laser beams into the optical fiber, after long-distance transmission, then transformed into parallel lights through collimating mirror to be focused on the work piece to implement the welding. The welding methods include vertical welding, paraller welding, stitch welding and so on.

Features

1. Fast welding speed, 2~10 times faster than traditional welding.

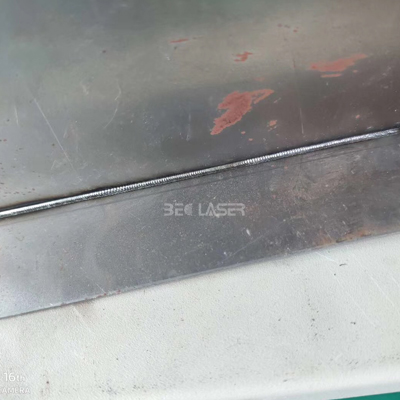

2. The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

3. The amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

4. High cooling rate, which can weld fine weld structure and good joint performance.

5. Laser welding has less consumables and long service life.

6. Easy operating need no training, more environmentally friendly.

Application

Laser welding can be used in welding stainless steel, aluminum, copper, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper - brass, titanium - gold, Titanium - molybdenum, nickel - copper and so on.

Parameters

| Model | HW1000 | HW1500 | HW2000 |

| Laser Power | 1000W | 1500W | 2000W |

| Laser Wavelength | 1080±5 nm | ||

| Laser Source | Raycus ( MAX/JPT laser source optional) | ||

| Operation Mode | Continuous | ||

| Output Mode | Standard QBH | ||

| Welding System | QILIN-handheld wobble welding head | ||

| Wire Feeder | Auto wire feeder | ||

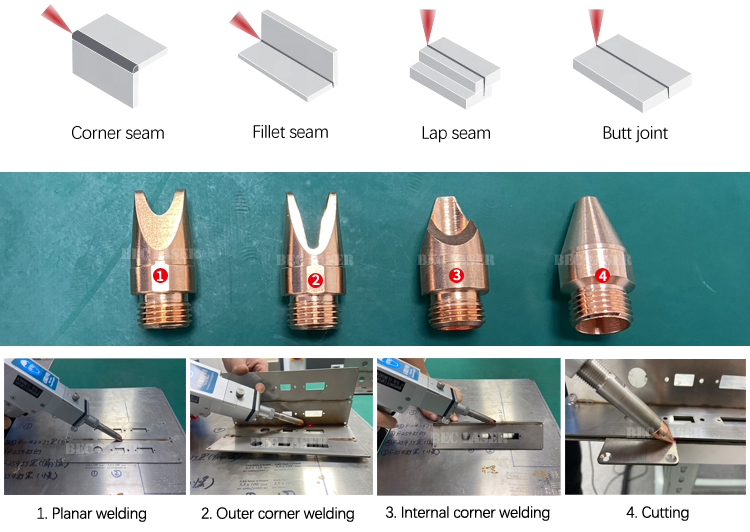

| Welding Nozzle | Planar, outer corner, inner corner, cutting nozzle | ||

| Modulation Frequency | 50~50,000Hz | 50~20,000Hz | 1~5,000Hz |

| Beam Quality | M2: 1.3 (25μm) | M2: 5-6 (50μm) | M2: 5-7 (50μm) |

| Red Guide Laser Power | 0.1~1 mW | 0.1~1 mW | 0.5~1 mW |

| Gas Protection | Nitrogen or Argon | ||

| Cooling System | Water cooling system | ||

| Working Temperature | 0 °C - 35 °C ( No condensation) | ||

| Total Power | ≤6KW | ≤7KW | ≤9KW |

| Power Requirement | 220V±10% 50Hz or 60Hz | 220V±10% 50Hz or 60Hz | 380V±10% 50Hz or 60Hz |

| Packing Size & Weight | Machine: Around 127*73*129cm, 198KG; Wire Feeder: Around 69*59*64cm, 48KG. |

||

Samples

Structures

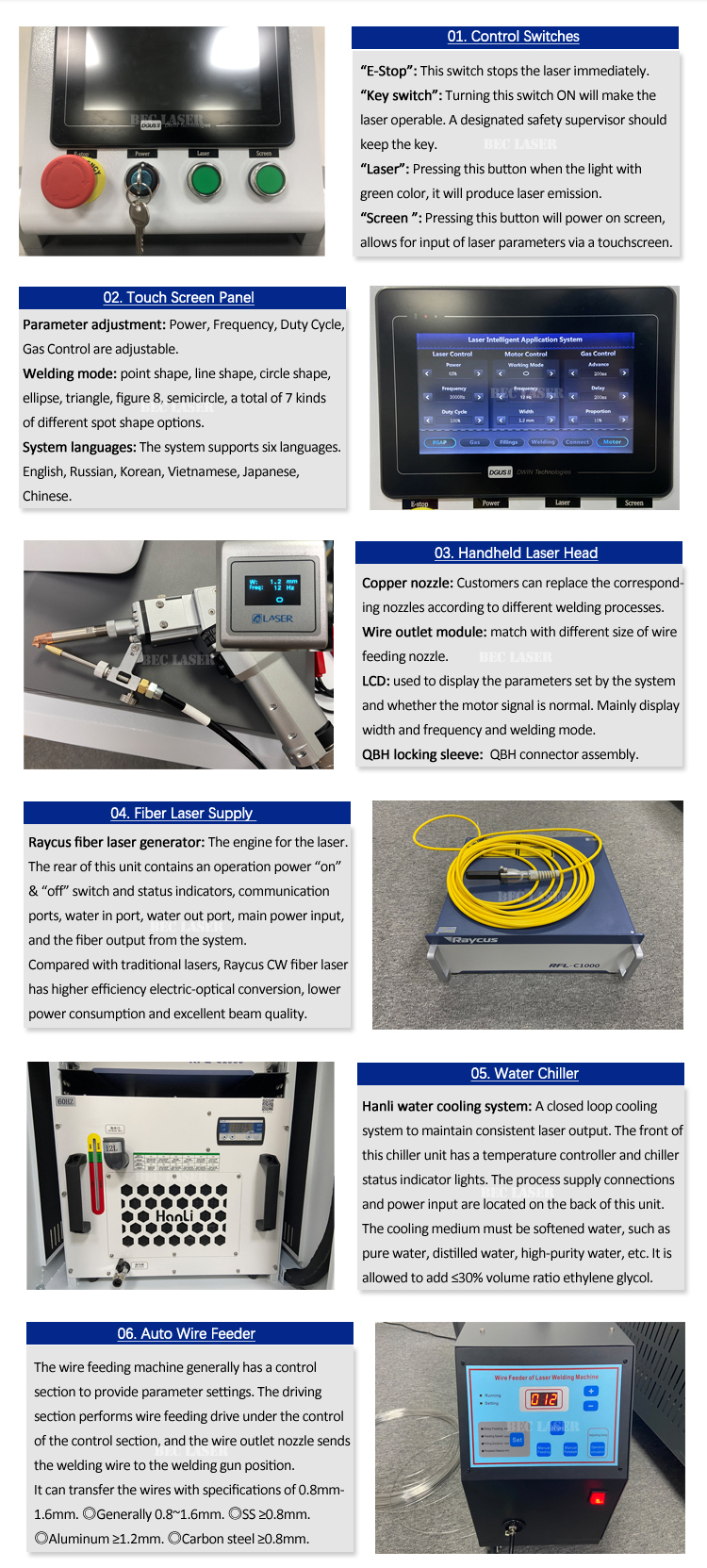

Details