CCD Visual Position Laser Marking Machine

Product Introduction

Based on the traditional marking machine, a high-pixel CCD camera is used to locate the current position of the product, and the position information of one or more products collected in real time is transmitted to the marking control card through the computer in order to achieve precise marking.

The visual positioning and marking system realizes rapid positioning, marking multiple products at a time, and can also carry out automatic assembly line feeding, and then perform visual positioning and marking after positioning, saving labor, improving work efficiency, and easy to realize automatic production compatible with multiple products The assembly line saves a lot of cost for labor.

Compared with the traditional laser marking machine, the marking interval is faster, saving 3-5 times the time of handling the product, and the position accuracy is higher. With its unique positioning system, the CCD laser marking machine is especially suitable for the super-fine processing market, handicrafts, IC electronic parts, PPC circuit boards and other polymer materials surface marking.

CCD visual positioning laser marking machine is to establish a standard template of the product before

processing through the visual positioning system, and then in batch processing, the system will automatically take photos of the product. It can feed at will, achieving precise positioning and perfect marking, which greatly improves the marking efficiency.

Application

CCD vision positioning laser marking machine supports fiber laser UV laser CO2 laser. According to the material choose the suitable laser type. It is suitable for large workload, product positioning is difficult, workpiece diversity and complexity.

Parameters

| Model | F200TCVP | F300TCVP | F500TCVP |

| Laser Power | 20W | 30W | 50W |

| Laser Wavelength | 1064 nm | ||

| Single Pulse Energy | 0.67mj | 0.75mj | 1mj |

| M2 | <1.5 | <1.6 | <1.8 |

| Frequency Adjustment | 30~60KHz | 30~60KHz | 50~100KHz |

| Quantity of Workpiece | Within the capture area no limited. | ||

| Marking Speed | ≤7000mm/s | ||

| Software | BEC Laser- CCD visual posioning software | ||

| Field of View | Standard: 80mm×80mm (Customized) | ||

| Accuracy | ±0.1mm | ||

| Conveyor Belt | Speed adjustable (Customized) | ||

| Cooling System | Air cooling | ||

| Power Requirement | 220V±10% ( 110V±10%) /50HZ 60HZ compatible | ||

| Packing Size & Weight | Machine: Around 80*108*118cm, Gross weight around 150KG | ||

Features

1. Adopting high-precision visual positioning system, precise position and fast corresponding speed.

2. CCD visual positioning system supports mainstream lasers such as ultraviolet, optical fiber, CO2, etc., and is suitable for marking products with a variety of materials.

3. Any position, any angle, and any number of products, the visual positioning system automatically recognizes, automatically detects and locates, and automatically marks.

4. Dedicated precision synchronous conveyor belt supports stepping mode and photoelectric induction mode, which can be switched as required.

5. KKVS4.0 visual positioning software system, after years of optimization and verification, the interface is more friendly and easy to operate.

6. The conveyor belt can be customized according to the product size and product characteristics.

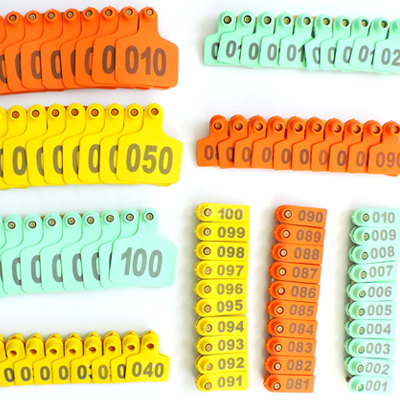

Samples